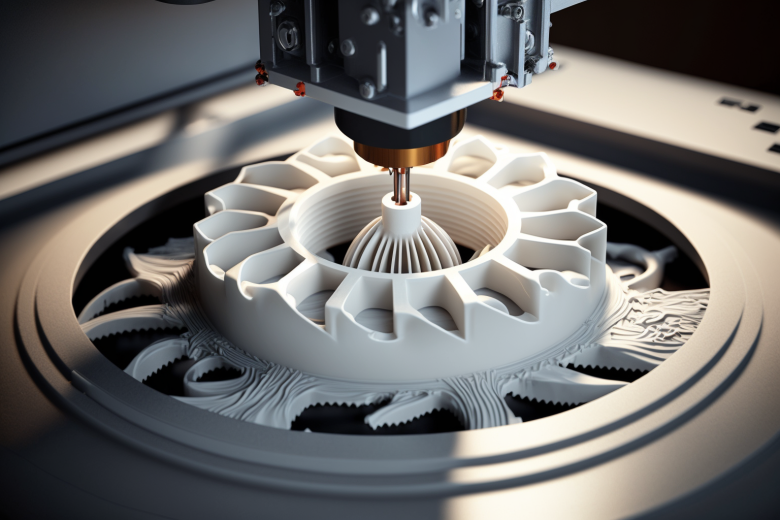

Additive manufacturing (AM) also known as 3D printing, is a transformative approach to industrial production that enables the creation of lighter, stronger parts and systems.

It is yet, another technological advancement made possible by the transition from analog to digital processes. In recent decades, communications, imaging, architecture and engineering have all undergone their own digital revolutions. Now, AM can bring digital flexibility and efficiency to manufacturing operations

AM is a trend that has only been accentuated by the pandemic, generating $12bn last year, up from $10.4bn the year before. Social distancing measures and a greater awareness of cleanliness, as well as a more home-based lifestyle, have made the prospect of remotely manufacturing a more attractive one than ever.

Below, we have summed up a few of the reasons why Additive Manufacturing is here to stay:

Companies are working more efficiently:

While this is always the case for any savvy company, the pandemic and its associated restrictions has brought about a sharper focus on working smart not hard.

3D printing makes many a manufacturing processes a lot more efficient, particularly with regards to tooling. It allows companies the ease of prototyping and testing within the same day. In this way, moulds and fixtures can be churned out as necessary during the production process.

Not wanting to rely on (and pay) a middleman to complete smaller tasks like these will certainly drive adoption.

The Covid-induced need for locally produced components:

Global lockdown restrictions quickly highlighted the fragility of existing supply chains. Many companies, left without crucial components, were left hanging without the parts needed to produce their products.

Additive manufacturing can help with this problem. What if, instead of outsourcing the physical product from China, merely the schematics were outsourced, allowing you to print your components anywhere you could set up a 3D printer.

The decentralisation of the production process would certainly help companies better brace themselves for similar events in the future.

The value of additive manufacturing is only just being realised

Although used in the context of prototyping and tooling, additive manufacturing is rarely used to do what it does best: to do things that no other manufacturing process can.

The wide variety of materials that can be used in 3D printing lend its application to vast array of different uses, from aerospace engineering to printing burgers.

A key use of additive manufacturing is its synergies with AI and machine learning. Programmes can trial and error designs within their own stress-testing algorithms, and produce better and stronger concepts as a result. Particularly in aerospace engineering, additive manufacturing has been used to find more organic and stronger solutions to issues. Whereas conventionally a part may have been designed with strong, straight lines, the algorithm often finds that organic, swooping lines are stronger and more durable.

Investment in AM equipment is of course a barrier to businesses ability to harness the opportunities presented. If this is the case for you please get in touch, we know a number of funder looking to help you meet your goals.

We need to harness the core values of technologies like additive manufacturing to move towards new ways of thinking and doing that have meaningful impact